From power grids to water treatment plants, much of the world’s essential infrastructure runs on systems we rarely notice but depend on every single day. At the center of these operations lies SCADA (Supervisory Control and Data Acquisition), a technology that seamlessly manages real-time monitoring, control, and automation. As industries become more complex and data-driven, understanding SCADA’s role is crucial to enabling safer, smarter, and more sustainable operations.

What is SCADA?

Supervisory Control and Data Acquisition (SCADA) systems are digital platforms designed to monitor and control industrial processes in real time. They function as the nervous system of critical infrastructure, collecting, analyzing, and visualizing operational data to ensure safe, reliable, and efficient performance.

SCADA systems typically consist of four core components:

- Remote Terminal Units (RTUs): Collect data from field sensors, such as pressure, temperature, or flow, and send it to the central control system.

- Programmable Logic Controllers (PLCs): Industrial computers that execute automated commands, including opening valves or stopping machinery.

- Human-Machine Interfaces (HMIs): Dashboards that allow operators to visualize data, issue commands, and assess system health.

- Communication Infrastructure: Networks, wired or wireless, that securely transmit data between field devices and control centers.

Together, these elements ensure real-time situational awareness and reliable control across complex industrial environments.

The Layered Design of SCADA Systems

SCADA architecture is structured in layers. At the field level, sensors and actuators capture environmental and operational data. RTUs and PLCs process this information locally before sending it to a centralized SCADA server through Ethernet, radio, or cellular networks.

Operators then interact with this data via HMIs that present real-time system conditions. As industries adopt edge computing, more decisions can be made near the source of data for faster response times. Meanwhile, cloud-based SCADA enables broader visibility, advanced analytics, and remote accessibility, connecting multiple sites across regions.

This continuous cycle of data acquisition, transmission, visualization, and control forms the backbone of centralized industrial operations.

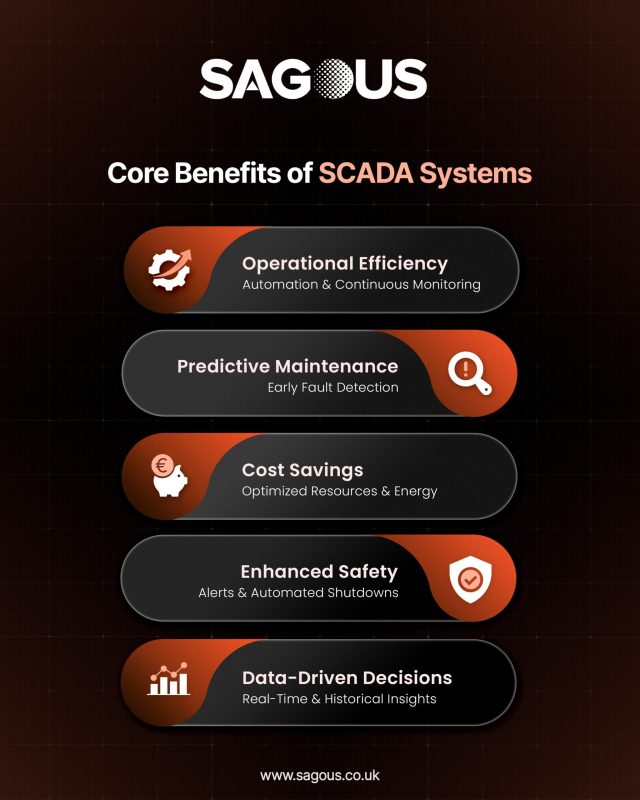

Key Benefits of SCADA Across Industries

- Operational Efficiency: Automates processes, reduces human error, and supports continuous monitoring.

- Predictive Maintenance: Detects early signs of equipment degradation to avoid downtime.

- Cost Savings: Boosts efficiency in resource usage, energy consumption, and labor.

- Enhanced Safety: Issues alerts or initiates shutdowns when conditions exceed safe thresholds.

- Data-Driven Decisions: Leverages real-time and historical data to improve performance.

Real-World Impact: How SCADA Powers Diverse Industries

SCADA is essential across numerous sectors:

- Power & Utilities: Monitors electricity flow, identifies faults, and manages load distribution.

- Oil & Gas: Controls refinery operations, pipeline monitoring, and drilling processes.

- Water & Wastewater: Supports treatment automation, quality monitoring, and overflow management.

- Manufacturing: Tracks machinery health and optimizes production lines.

- Transportation & Rail: Enables real-time traffic control and power management.

- Renewable Energy: Enhances wind, solar, and hydro generation with real-time environmental inputs.

- Smart Buildings: Automates HVAC, lighting, safety systems, and energy optimization.

- Mining & Heavy Industries: Ensures safe operations for ventilation, conveyors, and machinery.

- Food, Pharma & Packaging: Maintains compliance, quality control, and traceability.

SCADA vs. EMS: Control Meets Efficiency

SCADA systems excel in real-time monitoring and control, while Energy Management Systems (EMS) focus on optimizing energy usage. SCADA ensures processes run smoothly, whereas EMS analyzes consumption patterns to improve efficiency.

When integrated, EMS insights can prompt SCADA-driven operational adjustments, such as shifting loads during peak hours, allowing industries to reduce energy costs while improving sustainability.

SCADA in the Age of AI, IoT, and Cloud

Emerging technologies are transforming SCADA systems:

- AI & Machine Learning: Predict failures, detect anomalies, and optimize processes.

- IoT Sensors: Provide granular visibility into pipelines, tanks, equipment, and more.

- Cloud SCADA: Offers multi-site visibility, remote access, advanced analytics, and scalable computing.

These innovations elevate SCADA from reactive monitoring to proactive, intelligent decision-making.

Cybersecurity in SCADA: Securing Critical Infrastructure

As SCADA becomes increasingly interconnected, cyber risks grow. A compromised SCADA system can disrupt power, contaminate water, or halt manufacturing, making security essential.

Key cybersecurity practices include:

- Network Segmentation: Separating OT from IT networks to reduce exposure.

- Encrypted Protocols: Preventing data interception.

- Access Controls: Enforcing least-privilege access and MFA.

- Patch Management: Fixing known vulnerabilities promptly.

- Continuous Monitoring: Detecting intrusions early through IDS tools.

Compliance with standards like NERC CIP and IEC 62443 is now an industry expectation.

Sustainability and SCADA: Enabling Greener Operations

SCADA supports sustainability goals by:

- Reducing Waste: Optimizing resource and energy consumption.

- Supporting Renewables: Balancing fluctuating renewable energy sources with operational needs.

- Tracking Emissions: Supporting ESG reporting and carbon accounting.

- Improving Efficiency: Shifting energy-hungry activities to off-peak hours.

For industries with strict environmental targets, SCADA acts as a critical tool for sustainable operations.

Implementation Challenges and How to Overcome Them

Common challenges include:

- Legacy Integration: Older systems may require converters or modular upgrades.

- Skill Gaps: Training and simulation tools can help operators adapt.

- Budget Constraints: Scalable rollouts allow phased adoption and faster ROI.

- Vendor Lock-In: Open standards offer better long-term flexibility.

- Resistance to Change: Pilots and clear ROI communication build internal support.

- Data Overload: AI-based analytics help filter and prioritize insights.

Working with experienced integration partners ensures smoother adoption and long-term success.

Conclusion: From Control to Strategic Intelligence

SCADA has evolved beyond monitoring, it has become a strategic driver of industrial performance. With AI, IoT, and cloud advancements, SCADA systems are shifting from reactive control to predictive intelligence. Organizations embracing modern SCADA architectures position themselves for greater resilience, efficiency, and innovation.

Modern SCADA Starts with Strategic Expertise

SCADA modernization requires the right combination of technical expertise and strategic vision, balancing operational reliability with continuous innovation.

Sagous Limited provides both advanced technology solutions and skilled manpower to support intelligent automation, secure integrations, and scalable infrastructure across industries. With Sagous as your partner, your organization can operate smarter, accelerate performance, and stay ahead in the evolving future of connected operations.